|

IMPORTANT

|

|

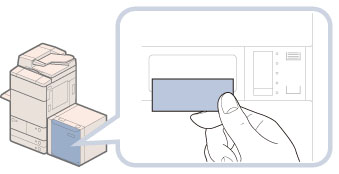

If the machine is in the Sleep mode (the touch panel is not displayed, and only

is lit), you may be unable to open the paper deck unit. In this case, press is lit), you may be unable to open the paper deck unit. In this case, press  to reactivate the machine, and then press the open button on the paper deck unit. to reactivate the machine, and then press the open button on the paper deck unit. |

|

NOTE

|

||||

|

The Paper Deck Unit-A1 and Paper Deck Unit-D1 are optional products.

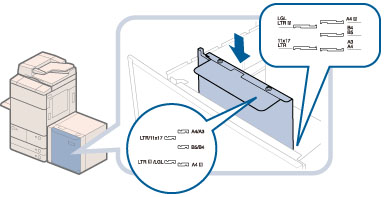

The following paper sizes can be loaded into the Paper Deck Unit-A1 or Paper Deck Unit-D1:

The paper size of the Paper Deck Unit-A1 is fixed to LTR. For instructions on changing the paper size that can be loaded in the Paper Deck Unit-A1, contact your local authorized Canon dealer.

|

CAUTION CAUTION |

|

When handling paper, take care not to cut your hands on the edges of the paper.

|

|

IMPORTANT

|

|

The Paper Deck Unit-A1 and Paper Deck Unit-D1 can only accommodate paper from 14 lb bond to 80 lb cover (52 to 220 g/m2) in weight.

If paper runs out and printing is stopped when you are printing in the Staple mode, do not remove the output sheets that are waiting to be stapled. (Printing and stapling resume after you clear the paper jam.)

|

|

NOTE

|

|

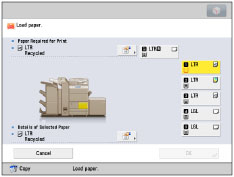

If a message prompting you to load paper appears during printing, the remaining prints are automatically made after you load the correct paper. If you select a different paper source, the remaining prints are made after you press [OK].

|

|

|

|

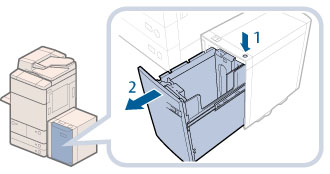

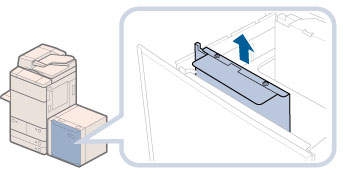

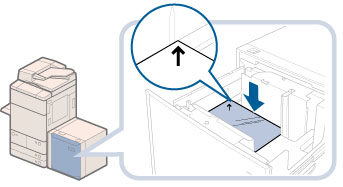

The inside lifter automatically descends to the paper loading position.

|

|

NOTE

|

|

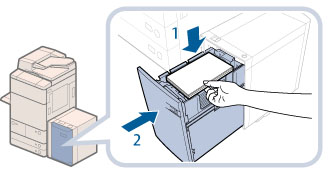

For high-quality printouts, use paper recommended by Canon.

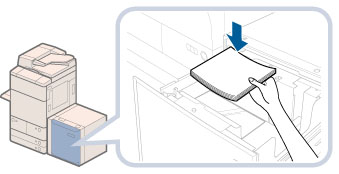

Before loading paper, always fan the sheets several times, and align the edges to facilitate feeding.

|

|

|

|

The inside lifter automatically ascends, and the machine becomes ready for printing.

|

CAUTION CAUTION |

|

When closing the paper deck unit, be careful not to get your fingers caught, as this may result in personal injury.

|

|

IMPORTANT

|

|

Do not load the following types of paper into the Paper Deck Unit-A1/Paper Deck Unit-D1. Doing so may cause a paper jam.

Severely curled or wrinkled paper

Thin straw paper

Heavy paper (more than 80 lb cover (220 g/m2))

Paper which has been printed on using a thermal transfer printer

The reverse side of paper which has been printed on using a thermal transfer printer

Coated paper

Tracing paper

Transparencies

Tab paper

Labels

Paper which is curled must be straightened out before loading it into the paper deck unit.

Do not load paper into the Paper Deck Unit-A1/Paper Deck Unit-D1 that has been previously copied onto, as this may result in a malfunction or damage to the machine. Always use the multi-purpose tray to feed paper when you want to copy onto the back of a sheet of paper that already has something copied on its front side (2nd side of 2-Sided copy).

Never place paper or any other items in the empty part of the paper deck unit next to the paper stack. Doing so may cause paper jams.

You will not be able to make copies or print if you load paper that exceeds the loading limit mark (

), or if the paper drawer is not completely pushed into the paper deck unit. ), or if the paper drawer is not completely pushed into the paper deck unit.Make sure that the height of the paper stack does not exceed the loading limit mark (

). ).Always check that the paper deck unit is in place.

|

|

NOTE

|

|

Load the paper stack in stages, adding approximately 550 sheets of paper at a time. If the Paper Deck Unit-A1/Paper Deck Unit-D1 can accommodate more paper, the lifter will descend.

If there are instructions on the paper package about which side of the paper to load, follow those instructions.

When paper is loaded in the Paper Deck Unit-A1/Paper Deck Unit-D1, the side facing up is the one printed on.

If problems, such as poor print quality or paper jams occur, try turning the paper stack over and reloading it.

For more information on the print direction of preprinted paper (paper which has logos or patterns already printed on it), see "Relationship Between the Original Orientation and Paper Orientation."

Rewrap any remaining paper in its original package, and store it in a dry place, away from direct sunlight.

If paper runs out and printing is stopped, load a new paper stack. Printing restarts after the new paper stack is loaded.

|

|

|

|

The inside lifter automatically descends to the paper loading position.

|

|

|

NOTE

|

|

It may take some time for the paper deck to open, even if you press the open button.

|

|

IMPORTANT

|

|

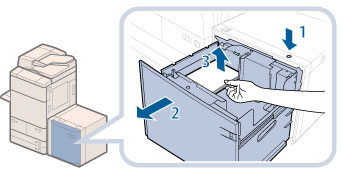

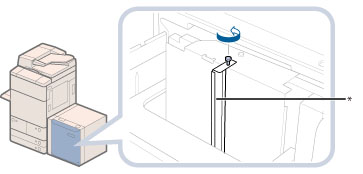

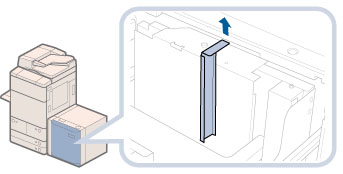

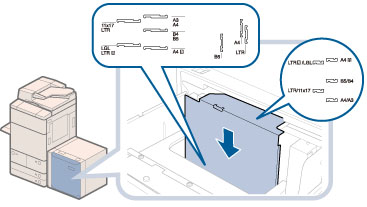

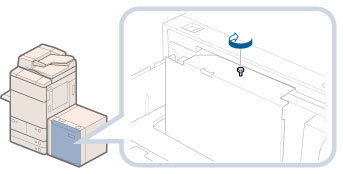

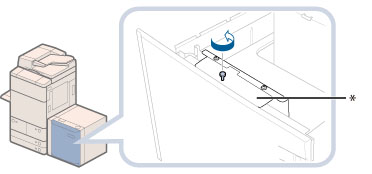

If the back size switch plate B is not adjusted properly for the paper size loaded in the paper deck, the correct paper size may not appear on the touch panel display.

Adjust the back size switch plate B correctly to avoid causing a paper jam, dirty prints, or make the inside of the machine dirty.

|

|

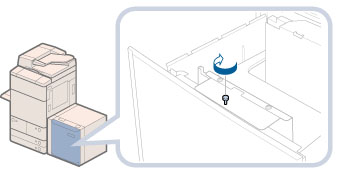

IMPORTANT

|

|

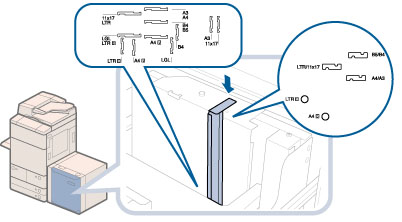

If the back size switch plate A is not adjusted properly for the paper size loaded in the paper deck, the correct paper size may not appear on the touch panel display.

Adjust the back size switch plate A correctly to avoid causing a paper jam, dirty prints, or make the inside of the machine dirty.

|

|

IMPORTANT

|

|

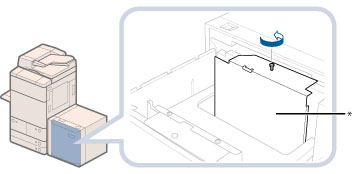

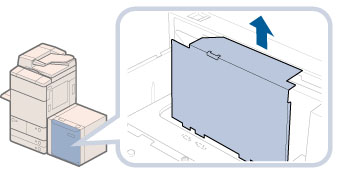

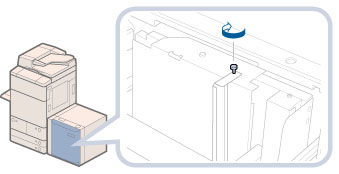

If the front size switch plate is not adjusted properly for the paper size loaded in the paper deck, the correct paper size may not appear on the touch panel display.

Adjust the front size switch plate correctly to avoid causing a paper jam, dirty prints, or make the inside of the machine dirty.

|

CAUTION CAUTION |

|

When closing the paper deck, be careful not to get your fingers caught, as this may result in personal injury.

|