(Start). The machine automatically feeds the originals to the platen glass and scans them. Two-sided originals can also be scanned as two-sided documents.

(Start). The machine automatically feeds the originals to the platen glass and scans them. Two-sided originals can also be scanned as two-sided documents. (Start). The machine automatically feeds the originals to the platen glass and scans them. Two-sided originals can also be scanned as two-sided documents.

(Start). The machine automatically feeds the originals to the platen glass and scans them. Two-sided originals can also be scanned as two-sided documents.|

IMPORTANT

|

|

Thin originals may become creased, if used in a high temperature or high humidity environment.

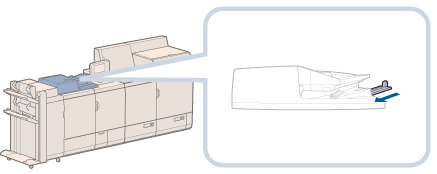

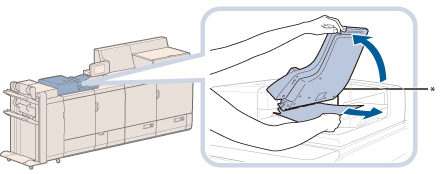

If you scan long originals, whose width is 17" to 24 7/8" (432 mm to 630 mm), from the feeder, the Auxiliary Original Output Tray should not be pulled out in order to prevent scanned originals from creasing.

In this case, support originals by hand when feeding and outputting paper.

Do not place the following types of originals into the feeder:

Originals with tears or large binding holes

Severely curled originals or originals with sharp folds

Clipped or stapled originals

Carbon backed paper or other originals which may not feed smoothly

Transparencies and other highly transparent objects

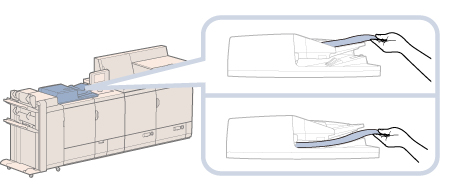

Always smooth out any folds in your originals before placing them into the feeder.

|

CAUTION CAUTION |

|

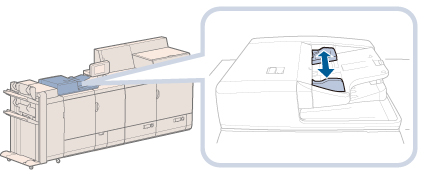

Do not insert your hands in the gap in the original supply tray, as doing so may cause injury.

|

|

IMPORTANT

|

|

Do not drop clips or other objects into the gap in the original supply tray.

Do not add or remove originals while they are being scanned.

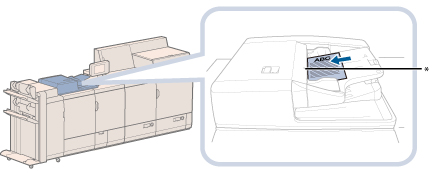

When scanning is complete, remove the originals from the original output area to avoid paper jams. (When you use the Duplex Color Image Reader Unit-K1, the Original Output Indicator blinks for a certain time when scanning is complete.)

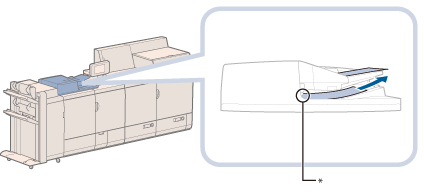

* Original Output Area

Do not place items in the original output area, as doing so may cause damage to your originals.

|

|

NOTE

|

|

When you are enlarging an LTR or STMT original onto 11" x 17" or LGL paper, place the original horizontally.

The scanned originals are output to the original output area in the order they are fed into the feeder.

You can place different size originals together into the feeder if you set the Different Size Originals mode. For more information, see the following:

Different Size Originals for Copy

Different Size Originals for Scan and Store

Different Size Originals for Scan and Send

|

|

IMPORTANT

|

|

Limit repeated feeding to a maximum of 30 times (this number varies, depending on the type and quality of the original). If the same original is fed through the feeder repeatedly, the original may fold or become creased, and make feeding impossible.

If the feeder rollers are dirty from scanning originals written in pencil, perform the feeder cleaning procedure. (See "Routine Cleaning.")

|