|

IMPORTANT

|

|

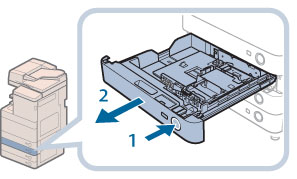

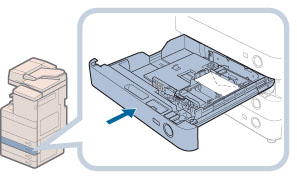

The Envelope Feeder Attachment-D1 can only be attached to Paper Drawer 2.

|

|

IMPORTANT

|

|

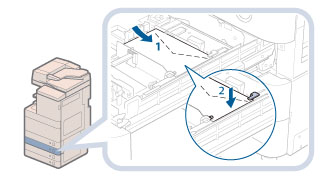

When you attach the Envelope Feeder Attachment-D1 to the paper drawer, do not forcefully move the front guide of the paper drawer in the wrong direction. Doing so may detach the Envelope Feeder Attachment-D1 from the paper drawer.

Do not print on both sides of an envelope. Doing so may cause paper jams, dirty prints, or make the inside of the machine dirty.

Do not load the following types of envelopes inside the envelope cassette. Doing so may cause paper jams, dirty prints, or make the inside of the machine dirty.

Curled, creased, or folded envelopes

Very thick or thin envelopes

Damp or wet envelopes

Torn envelopes

Irregularly shaped envelopes

Envelopes with clasps or windows

Envelopes that have already been sealed

Envelopes with holes or perforations

Envelopes with specially coated surfaces

Envelopes made of surface treated colored paper

Envelopes that are self-sticking, which use ink, glue, or other substances that can melt, burn, vaporize, or emit smells under the heat of a fixing unit (approximately 418°F). Depending on the materials used for the seal, the glue may melt under the fixing unit's heat, sealing the envelopes.

When the envelope cassette is attached and envelope is selected for the paper type, the envelope is ejected to the tray under the scanner unit.

If you are printing on envelopes, empty the output tray when up to 10 printed envelopes accumulate in the tray.

Envelopes should be stored in a place away from high-temperatures and humidity.

If there is a temperature difference between the location where the envelopes are stored and the location where the envelopes are being printed, leave the envelopes in the printing location at room temperature before you use them.

Correctly match the paper size dial, size switch, and [Register Envelope Drawer] in [Preferences] (Settings/Registration) with the size of the envelopes being loaded. Failure to do so may cause paper jams, dirty prints, or make the inside of the machine dirty.

If you want to adjust the width guides to load ISO-C5 envelopes, contact your local authorized Canon dealer.

|

|

NOTE

|

|

For more information on envelope types that can be loaded in the Envelope Feeder Attachment-D1, see "Available Paper Stock."

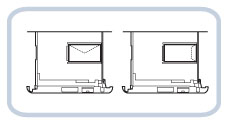

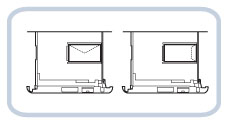

Sizes of the envelopes are as follows:

No. 10(COM10): 4 1/8" × 9 1/2" (104.7 mm × 241.3 mm)

Monarch: 3 7/8" × 7 1/2" (98.4 mm × 190.5 mm)

DL: 4 3/8" × 8 5/8" (110 mm × 220 mm)

ISO-C5: 6 3/8" × 9" (162 mm × 229 mm)

|

|

IMPORTANT

|

|

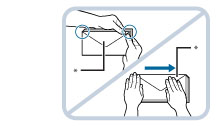

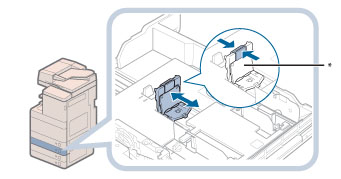

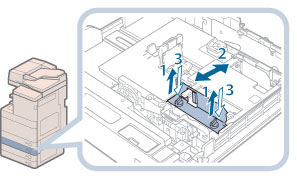

Using curled, creased, or folded envelopes may cause paper jams. Load envelopes after following the procedure below.

|

* Flap

|

|

IMPORTANT

|

|

If you use envelopes that have glue attached to their flaps, the glue may melt due to the heat and pressure of the fixing unit.

Take particular care to spread the envelopes out in the direction that they will be fed.

Do not print on the back side of the envelopes (the side with the flap).

If the envelopes become filled with air, flatten them by hand before loading them into the Envelope Feeder Attachment-D1.

|

|

|

|

|

|

IMPORTANT

|

|

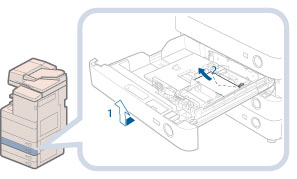

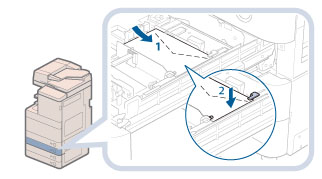

Envelopes which have been rolled or curled must be straightened out prior to use.

Make sure that the height of the envelope stack does not exceed the height limit mark (

). ).The maximum height (quantity) of envelopes that can be loaded into the cassette is approximately 1 1/4" (30 mm).

The maximum height (quantity) of envelopes varies, depending on the envelope type and user operating conditions, but as a reference, 1 1/4" (30 mm) is approximately 50 envelopes.

|

|

CAUTION CAUTION |

|

When returning the paper drawer to its original position, be careful not to get your fingers caught, as this may result in personal injury.

|

|

IMPORTANT

|

|

Never place paper or any other items in the empty part of the paper drawer next to the envelopes. Doing so may cause paper jams.

|

|

NOTE

|

|

If output has been stopped due to an insufficient number of envelopes, load more envelopes, and follow the instructions on the touch panel display. Printing resumes.

|

|

IMPORTANT

|

|

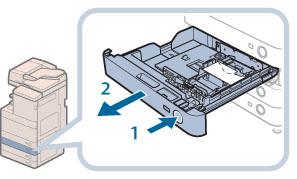

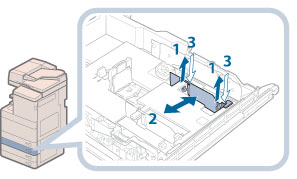

Make sure that you change the envelope settings from the Settings/Registration screen before carrying out the following procedure. (See "Designating the Envelope Type.") Otherwise, the machine may not recognize the changes you have made.

|

|

|

|

|

* Left Guide

|

|

|

|

|

|

|

IMPORTANT

|

|

Envelopes which have been rolled or curled must be straightened out prior to use.

Make sure that the height of the envelope stack does not exceed the height limit mark (

). ).The maximum height (quantity) of envelopes that can be loaded into the cassette is approximately 1 1/4" (30 mm).

The maximum height (quantity) of envelopes varies, depending on the envelope type and user operating conditions, but as a reference, 1 1/4" (30 mm) is approximately 50 envelopes.

|

|

NOTE

|

|

For details on how to change the registered envelope information for the drawer, see "Designating the Envelope Type."

|

CAUTION CAUTION |

|

When returning the paper drawer to its original position, be careful not to get your fingers caught, as this may result in personal injury.

|

|

IMPORTANT

|

|

Never place paper or any other items in the empty part of the paper drawer next to the envelopes. Doing so may cause paper jams.

|

|

NOTE

|

|

If output has been stopped due to an insufficient number of envelopes, load more envelopes, and follow the instructions on the touch panel display. Printing resumes.

|